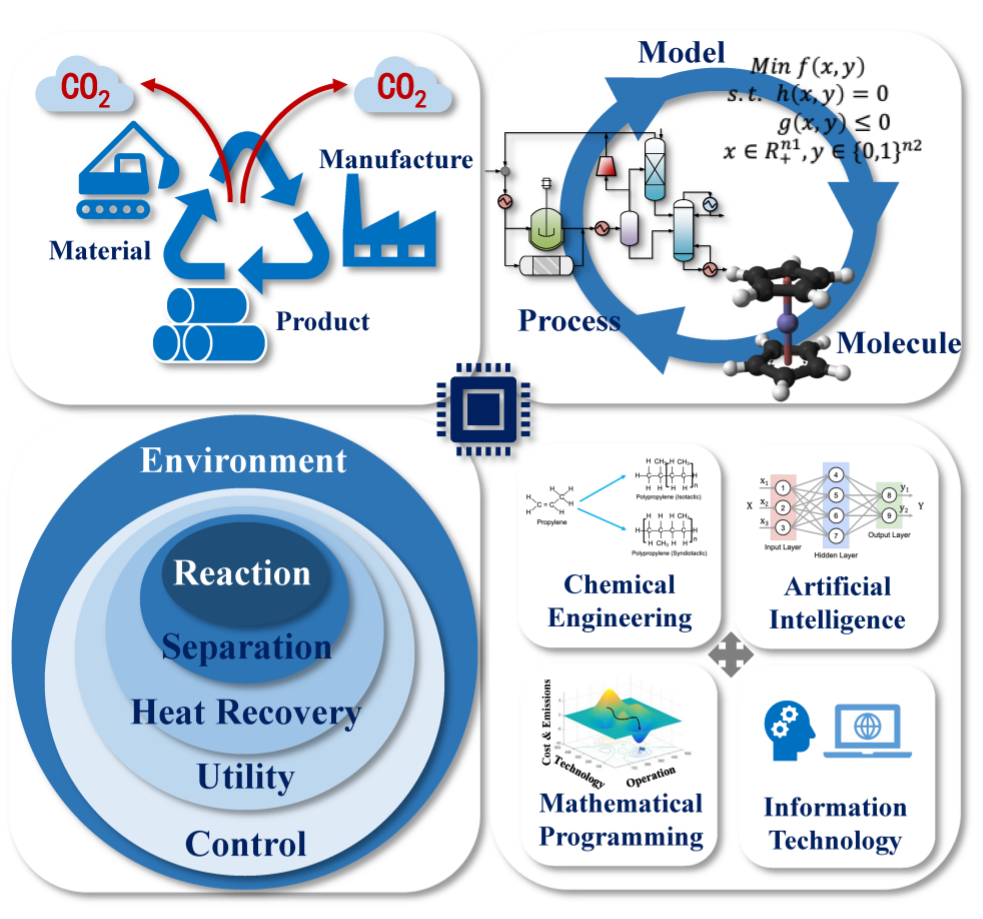

On-line inspection and intelligent control of chemical processes

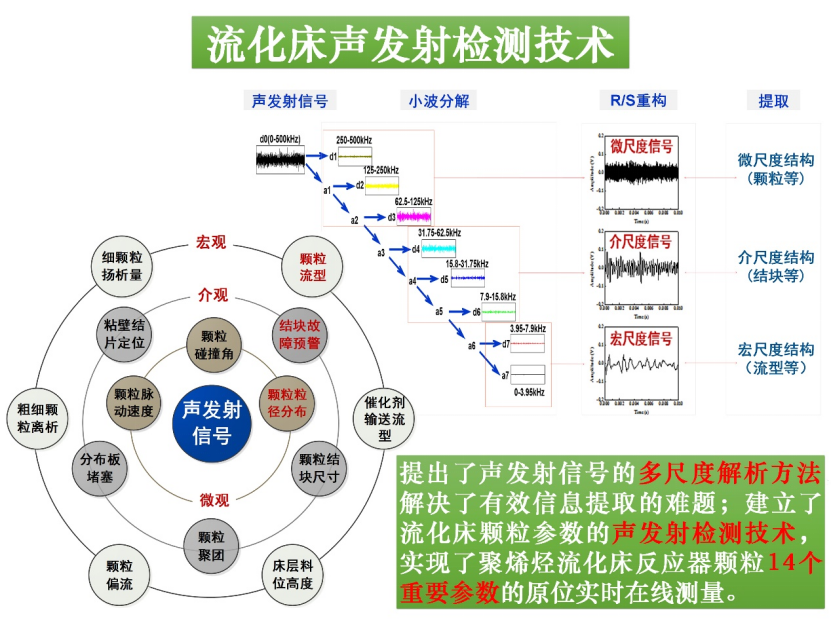

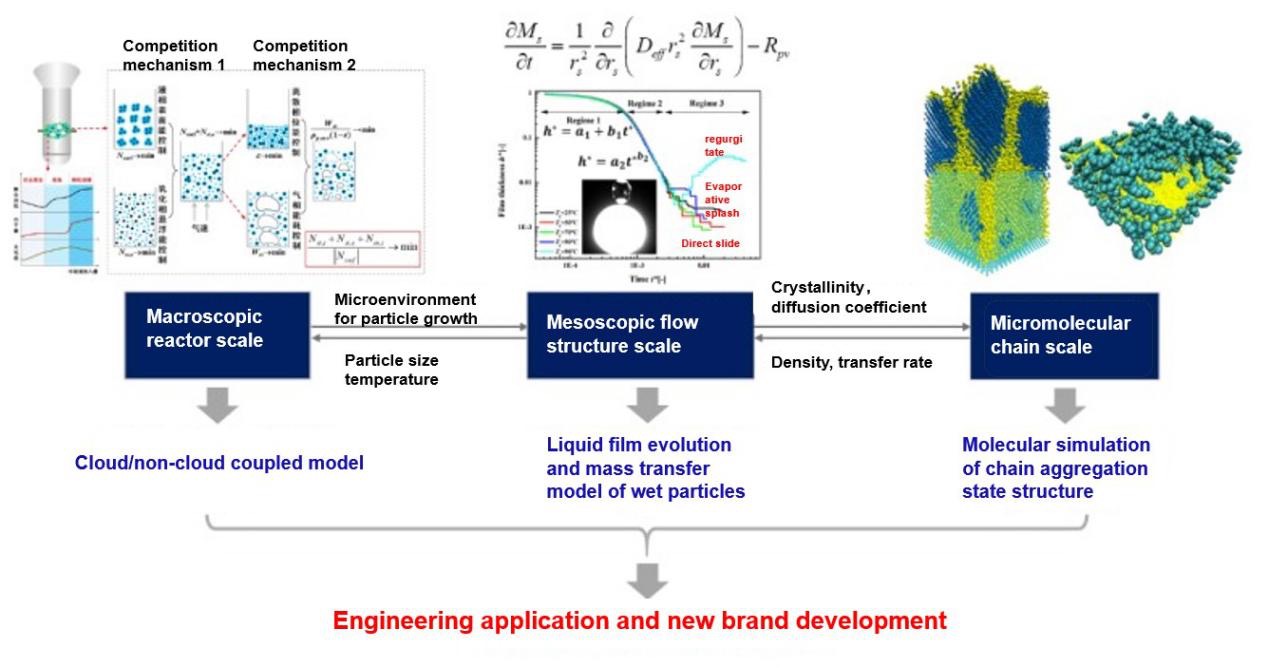

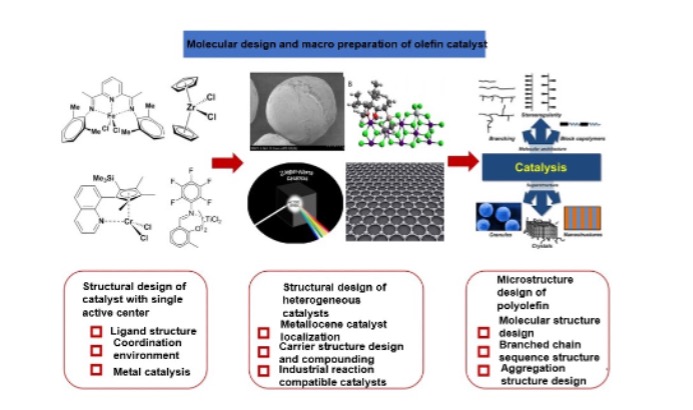

By using modern signal analysis methods and intelligent algorithms such as artificial neural network and deep learning, we can establish the correspondence between the characteristic parameters of chemical reaction process and multiphase flow and the signals of sound, light, electricity and magnetism, and realize the in-situ online detection of key reaction parameters and process parameters. To reveal the mechanism of chemical reaction, flow and mass transfer in multiphase reactor, to clarify the mechanism of chemical reaction, and to guide the design and operation optimization of chemical reactor.On this basis, the chemical process intelligent control system is built by combining chemical reaction kinetics and reactor mathematical model, and the intelligent control of industrial reactors is realized on the basis of soft measurement and online measurement of key process parameters, including maximum yield control, product quality control, grade switching process control and other functions. After the system is put into operation, it can significantly improve the smoothness of industrial plant operation and product quality, and significantly reduce energy and material consumption.Representative results include:l Fluidized bed reactor acoustic emission detection system. The acoustic emission technology is used to achieve online detection of more than ten key process parameters such as particle agglomeration, flow pattern and material level in the fluidized bed reactor of gas-phase polyethylene, which has been applied in more than 10 sets of large polyethylene plants.l Fluidized bed electrostatic detector. We have developed explosion-proof fluidized bed electrostatic detector and fluidized bed electrostatic detection system to realize online measurement of electrostatic potential and charge-to-mass ratio, early warning of agglomeration, and material level detection, etc. A total of 48 electrostatic detectors have been industrially applied in large polyolefin plants.l Intelligent monitoring system for polyolefin plant production process. Developed a decision support system for reactor operation optimization and accident stop warning, formed an intelligent monitoring system for polyethylene production process, and proposed a process to regulate flow patterns and destroy vortex hot spots to enhance heat transfer, which was verified by industrial tests. It has been applied in more than ten polyethylene industrial plants. Meanwhile, the results have been extended to be applied in coal gasification units, catalytic cracking units, polypropylene units, etc.